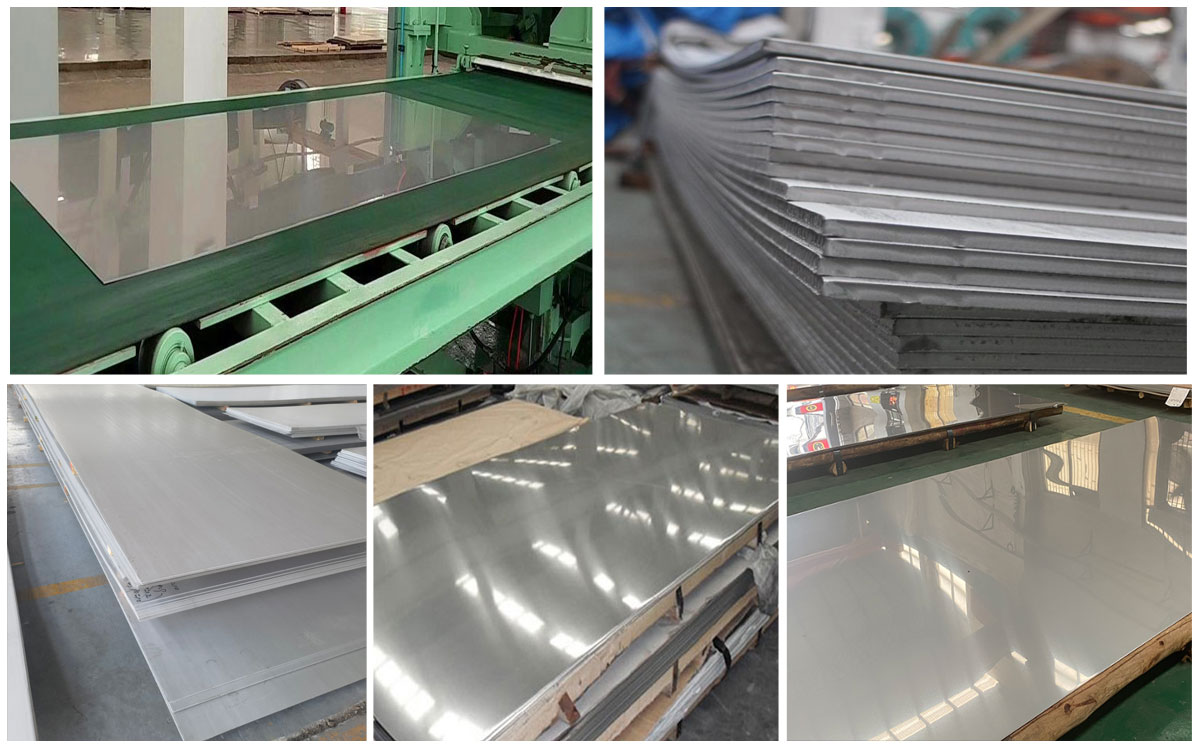

Stainless steel plate is a type of alloy steel plate that is highly resistant to rust. There are various types of stainless steel plates, each with distinct properties.

Product Name: | Stainless steel plate |

Type: | Plate |

Thickness: | 0.3-200mm |

Length: | 2000mm, 2438mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

Width: | 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

Standard: | ASTM, AISI, JIS, GB, DIN, EN |

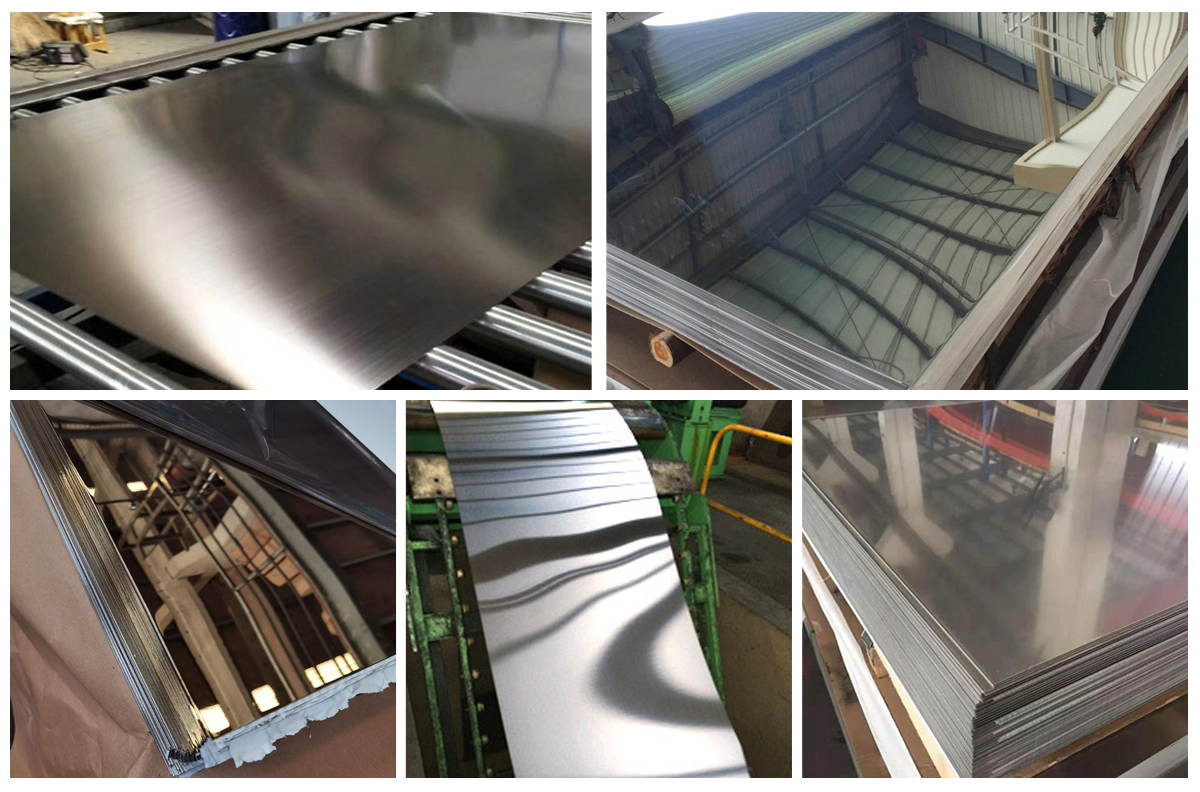

Surface: | BA, 2B, NO.1, NO.4, 4K, HL, 8K |

Application: | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. |

It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc | |

Certification: | ISO, SGS, BV |

Technique: | Cold Rolled Hot Rolled |

Edge: | Mill Edge Slit Edge |

Quality: | SGS Inspection |

Grade (ASTM UNS): | 304, 304L, 321, 316, 316L, 317L, 347H, 309S, 310S, 904L,S32205, 2507, 254SMOS, 32760, S31703, S31603,316Ti, S31635,S31254, N08926, 2205, S32205, S31008, S30908, S32750, S32760, 630 etc |

Grade (EN): | 1.4301, 1.4307, 1.4541, 1.4401, 1.4404, 1.4571, 1.4438, 1.4539,1.4547, 1.4529, 1.4410, 1.4501, 1.4462, 1.4845, 1.4542, ,etc |

Based on structural composition, stainless steel plates are classified into four main categories: austenitic stainless steel plates, martensitic stainless steel plates (including precipitation hardening types), ferritic stainless steel plates, and duplex stainless steel plates combining austenitic and ferritic structures.

According to primary chemical composition or characteristic elements, they can be divided into chromium stainless steel plates, chromium-nickel stainless steel plates, chromium-nickel-molybdenum stainless steel plates, low-carbon stainless steel plates, high-molybdenum stainless steel plates, and high-purity stainless steel plates.

By performance characteristics and application, stainless steel plates can be categorized as nitric acid-resistant, sulfuric acid-resistant, pitting corrosion-resistant, stress corrosion-resistant, and high-strength stainless steel plates.

From a functional standpoint, they include low-temperature stainless steel plates, non-magnetic stainless steel plates, free-cutting stainless steel plates, and superplastic stainless steel plates.

Based on the production process, stainless steel plates are generally classified as either hot-rolled or cold-rolled.

The most common classification method considers both structural and chemical composition characteristics. Under this approach, stainless steel plates are typically grouped into five categories: martensitic, ferritic, austenitic, duplex, and precipitation hardening stainless steels, or more broadly into two categories—chromium stainless steel and nickel stainless steel.

Surface Features & Manufacturing Methods & Applications of Stainless Steel Sheets

SURFACE | CHARACTERISTICS | SUMMARY OF MANUFACTURING METHOD | USE |

NO.1 | Silver | Hotrolled to specified thickness | No need for a glossy finish |

Matt | |||

NO.2D | Silver | Heat treatmentand picklingafter cold rolling | General materials, deep drawingmaterials |

NO.2B | Luster is stronger than No.2D | After NO.2D treatment the polishingrolleris used for the finalmild cold rolling | The general material |

BA | Brightas a mirror | Non - standard, butusuallybrightannealingsurface machining surface reflectivityis very high | Buildingmaterials, kitchenware |

NO.3N | Coarse grinding | Grind with 100-200# (unit grindingstrip) | Buildingmaterials, kitchenware |

NO.4N | Intermediategrinding | The polishedsurface obtainedby grindingwith 150-180# grindingstrip | Buildingmaterials, kitchenware |

NO.240 | Fine grinding | Grind with2408 grindingstrip | Kitchen utensils |

NO.320 | Very fine grinding | Grind with 320# grindingstrip | Kitchen utensils |

NO.400 | The gloss is close to BA | Grind with 400# polishingwheel | General timbec constructiontim bec kitchen utensils |

HL | Hairlinegrinding | Suitable particlematerials for hair texture grinding(150-240#) its grains are very large | Building buildingmaterial |

NO.7 | It's close to mirrorgrinding | Grind with 600# rotarypolishingwheel | For art or decoration |

8K | Mirror grinding | The mirroris ground witha polishingwheel | Reflector, decorative |

The stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion by acids, alkaline gases, solutions and other media. It is an alloy steel that does not rust easily, but not absolutely rust-free.

Wide range of uses Typical uses: pulp and paper equipment heat exchangers, mechanical equipment, dyeing equipment, film processing equipment, pipelines, exterior materials for buildings in coastal areas, etc.

FAQ:

Q: What products does your company have?

A: Our company produces all kinds of carbon steel plates, carbon steel coils, carbon steel pipes, carbon steel rods, carbon steel rebars, I-beams, H-beams, flat steels, channel steels, steel sheet piles, steel strands, etc. Rich production experience, support customization.

Q: What are the advantages of your company?

A: (1): Prime quality and Competitive price.

(2): Excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Samples can be provided as your requirements.

Q: What is your terms of payment ?

A: Can be negotiated by both parties. If you have another question, pls feel free to contact us as below.

Q: How long is your delivery time?

A: Stock steel/Steel for simple cutting/Small amount of general standard steel: about 5-20 days for delivery; Custom steel/bulk steel: about 15-30 days for delivery. Contact us for specific delivery times.