The steel strand is composed of multiple steel wires, which can be called PC Strand. The surface can be added with galvanized layer, zinc-aluminum alloy layer, aluminum clad layer (aluminum clad), copper plated layer, epoxy coated, etc. as required. In general, all kinds of steel strands should be delivered in coils. The specifications of the steel strands are 1*2, 1*3, 1*7 and 1*19, etc., usually followed by the single wire diameter, which is expressed as "1*19φ5", indicating that 1 steel strand consists of 19 Twisted steel wire with a diameter of 5mm.

Classification of steel strands

(1) Classification by use

Prestressed steel strands, galvanized steel strands (for electric power) and stainless steel strands, of which the prestressed steel strands are coated with anti-corrosion grease or paraffin and then wrapped with HDPE, called unbonded prestressed steel strands (unbonded steel strands) , Prestressed steel strands are also made of galvanized or galvanized aluminum alloy steel wire.

(2) Classification according to material properties

Steel strand, aluminum clad steel strand and stainless steel strand.

(3) Classification by structure

The prestressed steel strand can be divided into 7 wires, 2 wires, 3 wires and 19 wires according to the number of wires, and the most commonly used structure is 7 wires.

Galvanized steel strands and aluminum-clad steel strands for electric power are also divided into 2, 3, 7, 19, 37 and other structures according to the number of steel wires, and the most commonly used is the 7-wire structure.

(4) Classification by surface coating

It can be divided into (smooth) steel strands, galvanized steel strands, epoxy-coated steel strands, aluminum-clad steel strands, copper-coated steel strands, plastic-coated steel strands, etc.

Manufacturing process of steel strand

The manufacturing process is divided into monofilament manufacturing and stranded wire manufacturing. The (cold) wire drawing technology is used in the production of monofilament. According to the different materials of the product, it can be high carbon steel wire rod, stainless steel wire rod or medium and low carbon steel wire rod. Zinc, should be electroplated or hot dipped on monofilament. In the process of strand manufacturing, a stranding machine is used to twist multiple steel wires into a product. The prestressed steel strand also needs to be continuously stabilized after being formed. (reel-less) completed.

FAQ:

Q: What kind of work does your company do?

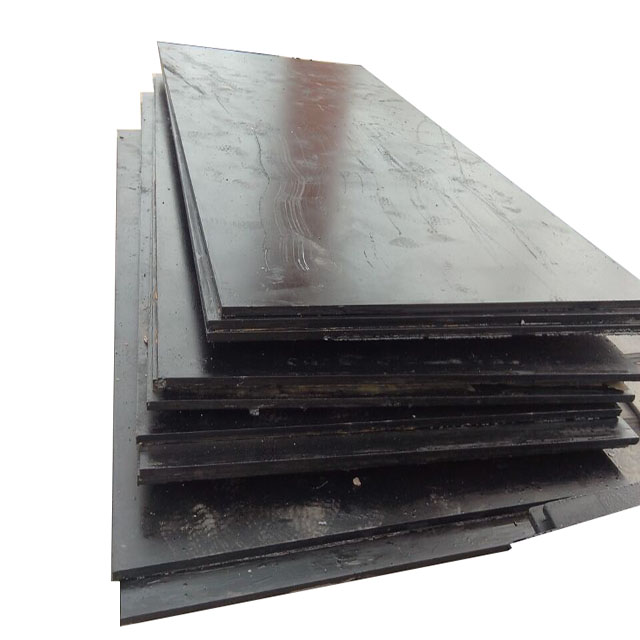

A: We are a business steel industry and trade.We mainly produces carbon steel plate/pipe/coil/bars, etc.

Q: What are the advantages of your company?

A: (1): Prime quality and reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Samples can be provided as your requirements.

Q: What is your terms of payment ?

A: Can be negotiated by both parties. If you have another question, pls feel free to contact us as below.

Q: What about your price?

A: Our price is very competitive.

Pls feel free to contact us if you are interested in our products.

Q: How long is your delivery time?

A: Different products have different delivery time. The products will be delivered as soon as possible on the basis of the quality assurance. Usually the delivery time is within 5-15 days after we received your balance.