Hot-rolled coil has excellent properties such as high strength, good toughness, easy processing and good weldability, so it is widely used in shipbuilding, automobile, bridge, construction, machinery, pressure vessel and other manufacturing industries. Common materials are Q235B, Q345B, SPHC, 510L, Q345A, Q345E, etc.

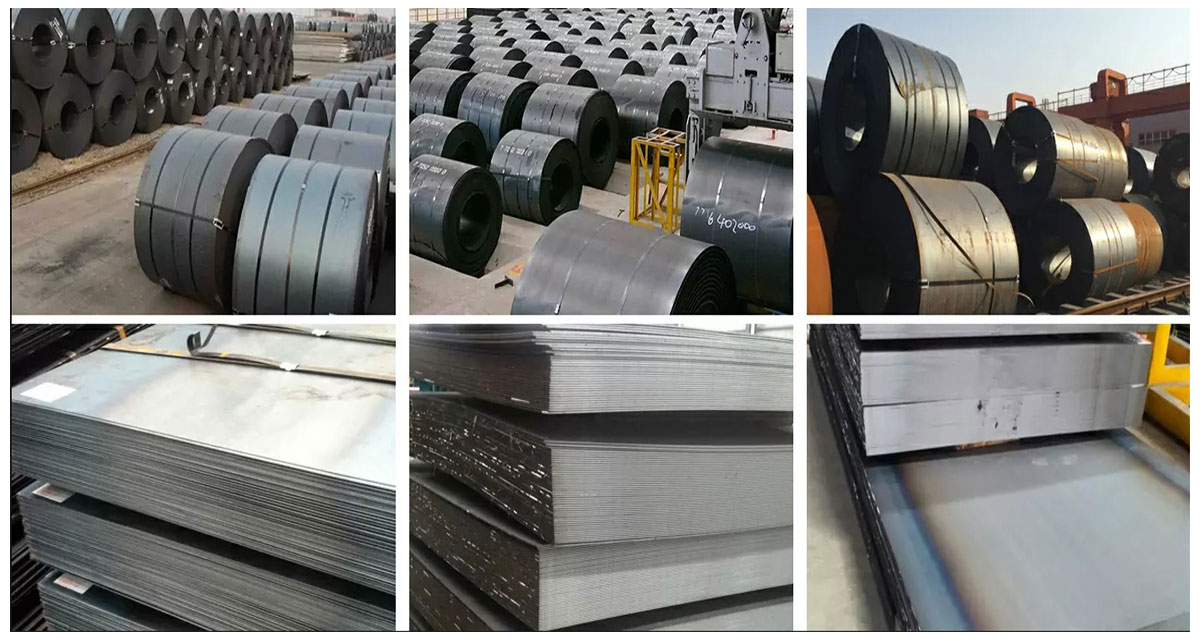

The difference between hot rolled coil and hot rolled sheet

Hot-rolled coils, also known as hot-rolled coils, are strips made of slabs (mainly continuous casting slabs) as raw materials, which are heated by rough rolling mills and finishing mills. The hot steel strip coming out of the last rolling mill of finishing rolling is cooled to a set temperature by laminar flow, and is rolled into a steel strip coil by a coiler.

Hot-rolled sheet, also known as hot-rolled sheet, is made of cooled steel strip coils. According to the different needs of users, through different finishing lines (leveling, straightening, cross-cutting or slitting, inspection and weighing, packaging and signs, etc.) to be processed into steel plates, flat rolls and slit steel strip products.

Advantages of hot rolled coil:

1. It has a high strength-to-weight ratio, making it ideal for construction and shipbuilding.

2. Highly resistant to corrosion and wear, very suitable for pressure vessels and piping systems.

3. It has excellent weldability and formability, making it suitable for various manufacturing processes.